A fuel cell is an electric power generator that is capable of producing electricity from hydrogen gas while discharging only water as a waste product. It is hoped that this highly efficient clean energy system will play a key role in the adoption of the hydrogen economy, replacing the combustion engines and batteries in automobiles and trucks, as well as power plants.

However, the cost of platinum, which can be up to ~30,000 USD per kg, has been a major limitation, making fuel cell catalysts to be prohibitively expensive. The production methods of highly-performing catalysts have also been complicated and largely limited. Accordingly, the development of a facile and scalable production method for platinum-based fuel cell catalysts is an urgent challenge, together with enhancing catalytic performance and stability while using a minimum amount of platinum.

To tackle this issue, a research team led by Prof. SUNG Yung-Eun and Prof. HYEON Taeghwan at the Center for Nanoparticle Research (CNR) within the Institute for Basic Science (IBS), South Korea has discovered a novel method for the production of nanocatalysts. The researchers demonstrated that these uniformly sized (3-4 nanometers) cobalt-platinum (Co-Pt) alloy nanoparticles can be produced by simple heat treatment. This method has combined features of the ease of the synthesis of the impregnation method, along with the precise control over the size and shape of the nanocrystals similar to the colloidal method.

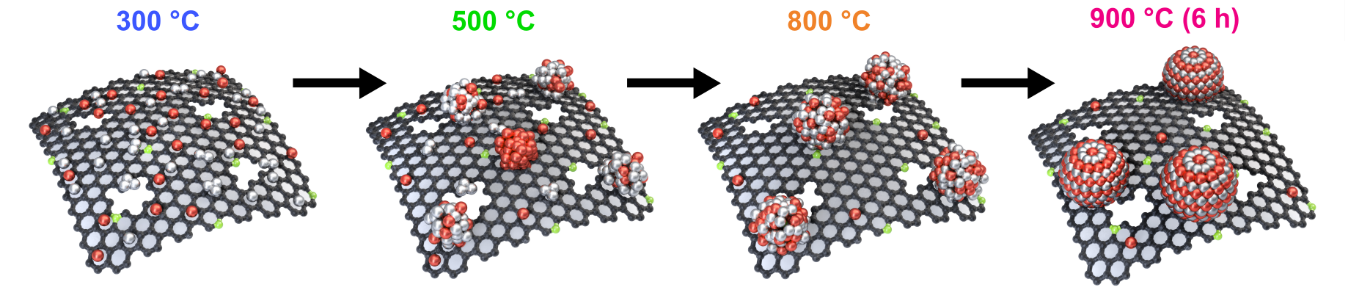

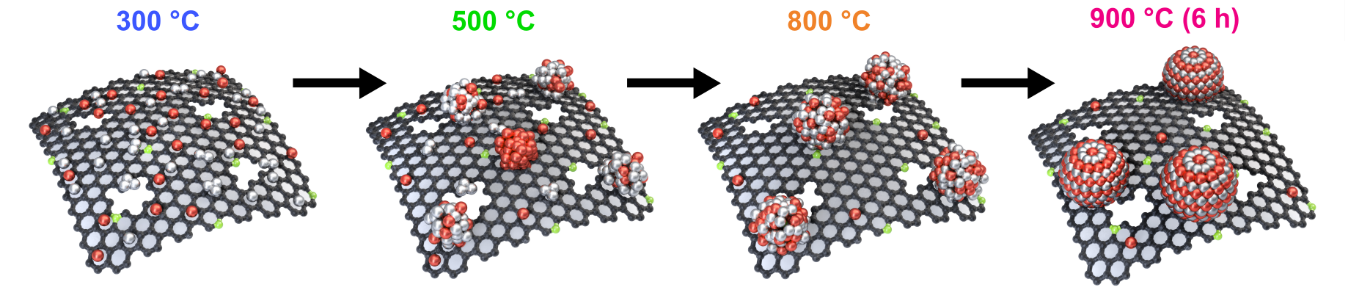

The novel Co-Pt alloy nanocatalysts developed by the CNR-IBS team consist of two oppositely-charged metal complexes, specifically Co and Pt ions surrounded by bipyridine and chlorine ligands, respectively. The research team hypothesized that a simple heat treatment would cause the bipyridine ligand to thermally decompose into a carbon shell that can protect the growing Co-Pt alloy nanoparticles. After optimizing the heat treatment condition, they succeeded in obtaining a highly uniform nanocatalyst with nanoparticles of only 3-4 nanometer sizes.

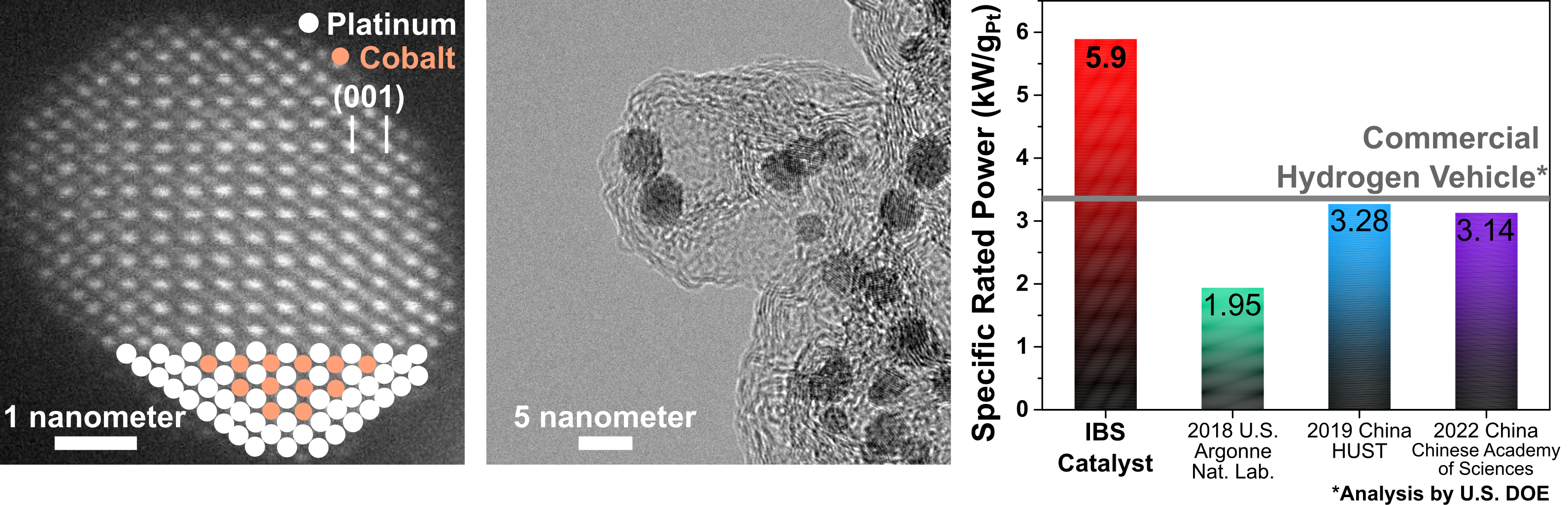

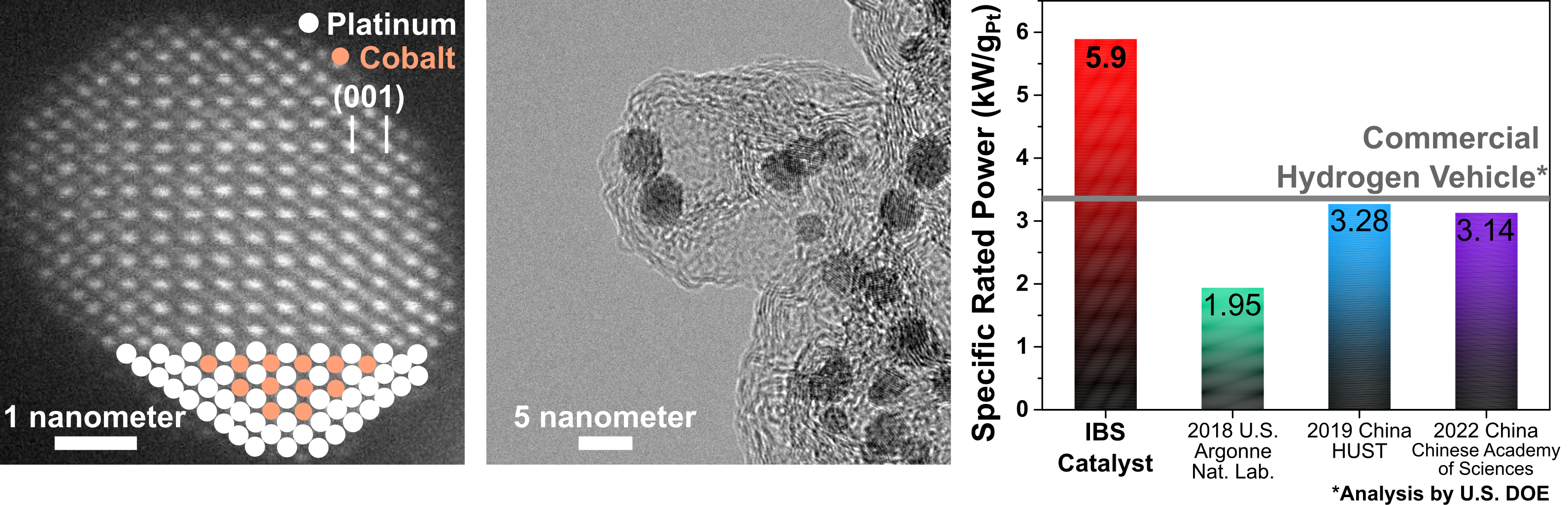

In the nanocatalyst developed by the group, Co and Pt atoms were arranged in a regular way called the ‘intermetallic phase’, where the unstable Co atoms are stabilized by the surrounding Pt atoms. Additionally, when nitrogen was effectively doped onto the carbon support, ionomers (proton conductors) were homogeneously dispersed over the entire catalyst layer in the fuel cell, which better facilitated the supply of oxygen gas to the surface of the Co-Pt nanocatalyst.

These structural features added up to a much-enhanced power performance in the proton-exchange-membrane fuel cell, exhibiting high specific rated power of 5.9 kW/gPt, which is about twice that of the current performance in a commercial hydrogen vehicle.1) The catalyst produced by the team has achieved most of the 2025 targets set by the U.S. Department of Energy (DOE) with the goal of stable long-term operation of the fuel cell.

The CNR-IBS team strongly believes that this study would stimulate the development of next-generation fuel cell catalysts. These findings would also contribute to the improvements in the catalytic performance and durability of alloy nanocatalysts for various other electrocatalytic applications.

Prof. Hyeon, stated, “Design of a novel bimetallic compound as a precursor material has been the critical starting point in this study. We have developed a platform technology to produce a complicated form of alloy nanocatalysts through a simple and scalable method, and finally achieved an enhanced fuel cell power performance with less amount of platinum used.”

Prof. Sung remarked, “A world-class level of fuel cell performance has been achieved in this research, surpassing most of the 2025 targets of U.S. DOE by lessening the amount of platinum that can contribute up to around 40% of the cost of fuel cells.” He added, “We expect that this study, together with some follow-up studies, would greatly impact the growth of the hydrogen vehicle industry and the realization of hydrogen economy in the near future.”

Figure 1. Microscopic (STEM and TEM) images of the developed catalyst and its PEMFC power performance. Compared to the state-of-the-art fuel cell catalysts, the catalyst developed by the CNR-IBS team showed almost twice the power performance per platinum use.

Figure 2. Schematic illustration of the growth process of the Co-Pt alloy nanocatalyst. Simple heat treatment at 900 °C could produce atomically ordered Co-Pt nanoparticles on a carbon support.

Notes for editors

- Reference

Tae Yong Yoo, Jongmin Lee, Sungjun Kim, Min Her, Shin-Yeong Kim, Young-Hoon Lee, Heejong Shin, Hyunsun Jeong, Arun Kumar Sinha, Sung-Pyo Cho, Yung-Eun Sung, and Taeghwan Hyeon. Scalable production of an intermetallic Pt–Co electrocatalyst for high-power proton-exchange-membrane fuel cells. Energy Environ. Sci., 2023. DOI: 10.1039/D2EE04211H

- Media Contact

For further information or to request media assistance, please contact Prof. Yung-Eun Sung at the Center for Nanoparticle Research, Institute for Basic Science (IBS) (ysung@snu.ac.kr) or William I. Suh at the IBS Public Relations Team (willisuh@ibs.re.kr).

- About the Institute for Basic Science (IBS)

IBS was founded in 2011 by the government of the Republic of Korea with the sole purpose of driving forward the development of basic science in South Korea. IBS has 4 research institutes and 33 research centers as of January 2023. There are eleven physics, three mathematics, five chemistry, nine life science, two earth science, and three interdisciplinary research centers.